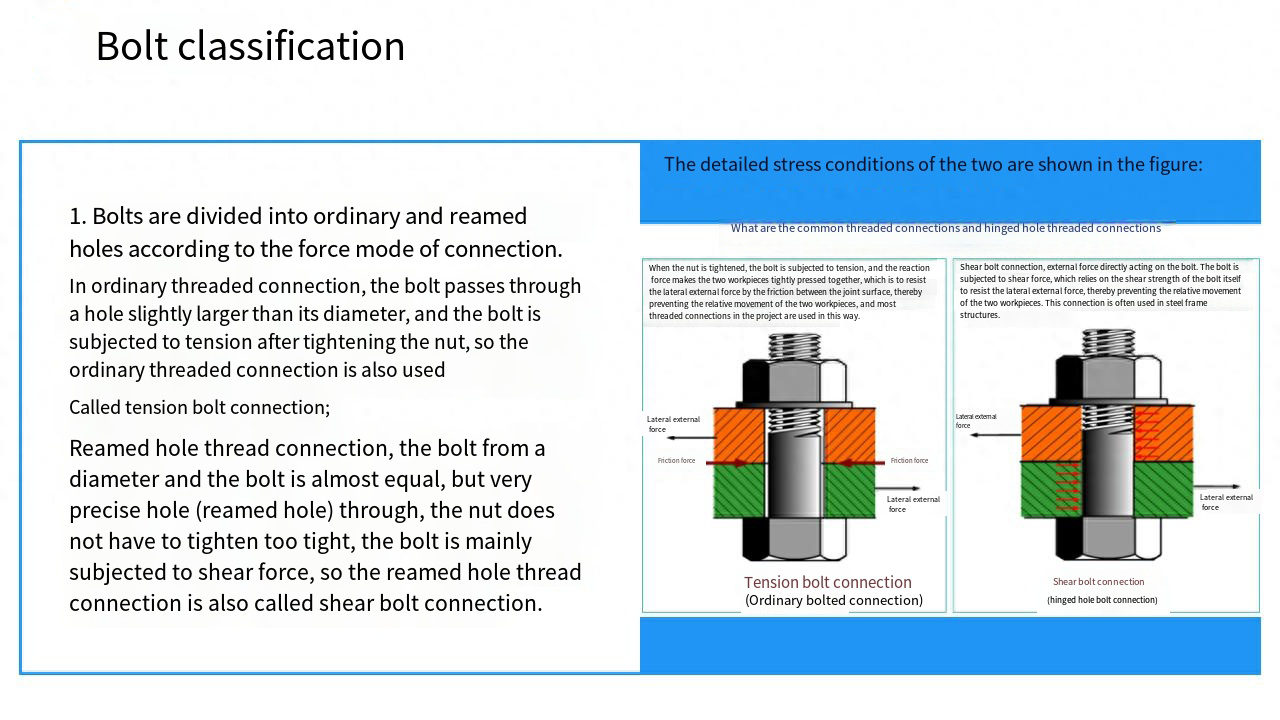

Ho ke ke ha thoe khoele tloaelehileng le reamed lesoba khoele, empa tloaelehileng bolt le reamed lesoba bolt, hobane khoele karolo ea tse peli e tšoanang, phapang ke hore karolo ea molamu ntle khoele.Hobane karolo ea khoele e tšoana, matla a axial a tšoana.Ho na le lekhalo pakeng tsa karolo e hlakileng ea karolo ea bolt e tloaelehileng le lesoba, 'me matla a pota-potileng ke ntlha feela ea khohlano holim'a sebaka sa ho kopana ha bolt e tiisitsoe (ehlile, haeba u hlile u nahana ho khaola, matla a hlabang. ha e le hantle ke matla a ho kuta a bolt).Ho lekana ha boutu ea lesoba le lesoba ke ho mamellana, 'me matla a mosehla ke matla a ho kuta a boutu ea lesoba le lecha.

Hlokomela

bm = 1d stud e habeli e sebelisoa hangata bakeng sa ho hokahanya likarolo tse peli tsa tšepe tse hoketsoeng;GB/T897-1988 “Double-ended stud bm=1d” (bm e bolela pheletso ya lesoba la screw e bitswang screw end, bolelele ba bm bo amana le thepa ya karolo e lokelang ho korojwa: bm=1d bakeng sa tshepe. le boronse, moo d e bolelang bophara bo ka ntle ba khoele, e bua ka bophara bo boholo.)

bm=1.25d le bm=1.5d double stud e sebediswa ka kakaretso bakeng sa kgokahanyo pakeng tsa sehokedi sa tshepe le sehokedi sa tshepe;GB898-1988 "Double stud bm = 1.25d", GB899-1988 "Double stud bm = 1.5d".

bm = 2d stud e habeli e sebelisoa hangata bakeng sa ho hokahanya sehokelo sa aluminium alloy le sehokelo sa tšepe.Sehokelo sa pele se fanoa ka lesoba le ka hare le khoele, 'me la ho qetela le na le lesoba la ka hare.GB/T900-1988 “Double stud bm =2d”.

Likhoele tse lipheletsong tse peli tsa stud e bolelele bo lekanang habeli li tlameha ho kopanngoa le linate le li-washer bakeng sa likarolo tse peli tse hokahantsoeng ka likoti.GB/T901-1988 “Equal length double stud Class B”, GB/T953-1988 “Equal length double stud Sehlopha sa C”.Qetello e 'ngoe ea sekoahelo sa welding e cheselitsoe ka holim'a karolo e hokahaneng,' me pheletsong e 'ngoe (qetellong e nang le likhoele) e feta karolong e hokahaneng e nang le lesoba la ho feta, ebe washer e kenngoa,' me linate li phunyeletsoa, ka hona. hore likarolo tse peli tse hokahaneng li hokahane ka kakaretso.GB/T902.1 “Welding stud for manual welding”, GB/T902.2 “Welding stud for arc stud welding”, GB/T902.3 “Welding stud for energy storage welding”, GB/T902.4 “Welding stud for arc stud welding” ho tjheseletsa ha ard stud ka nako e kgutshwane”.

Tlhokomeliso:

Khoele e sebelisitsoeng holim'a khoele e habeli (GB/T897-900) hangata ke khoele e mahoashe e tloaelehileng, 'me khoele e ntle e tloaelehileng kapa khoele ea transition fit le eona e ka sebelisoa ho latela tlhoko (ho latela GB1167/T-1996" transition fit thread. ”).Bolelele bo lekanang bo habeli ba hlooho ea hlooho -B sehlopheng, e ka sebelisoa ho latela tlhoko30Cr, 40Cr, 30CrMnSi, 35CrMoA40MnA kapa 40B tlhahiso ea thepa, ts'ebetso ea eona ho latela tumellano pakeng tsa mekha ea phepelo le tlhokahalo.Welding stud material chemical composition, ho latela GB/T3098 .1-2010 litokisetso, empa boholo ba eona ba carbon content ha boa lokela ho ba kholo ho feta 0.20%, 'me bo ke ke ba etsoa ka tšepe ea ho itšeha mahala.

6. Ho thatafala: Bokhoni ba thepa ea ho hanyetsa lintho tse thata tsa lehae tse hatelitsoeng ka holim'a eona ke pontšo ea ts'ebetso ea ho lekanya tekanyo ea bonolo le boima ba lisebelisoa tsa tšepe.Teko ea ho thatafala ha liteko (Brinell, Rockwell, Vickers)Litlhoko tsa ho lokisa sampole: Lipheletso tse peli tsa sampole lia bapisa, bokaholimo bo bataletse, 'me ha ho oli kapa oxide e lumelletsoeng.

Sebaka sa teko 10 ~ 35 °

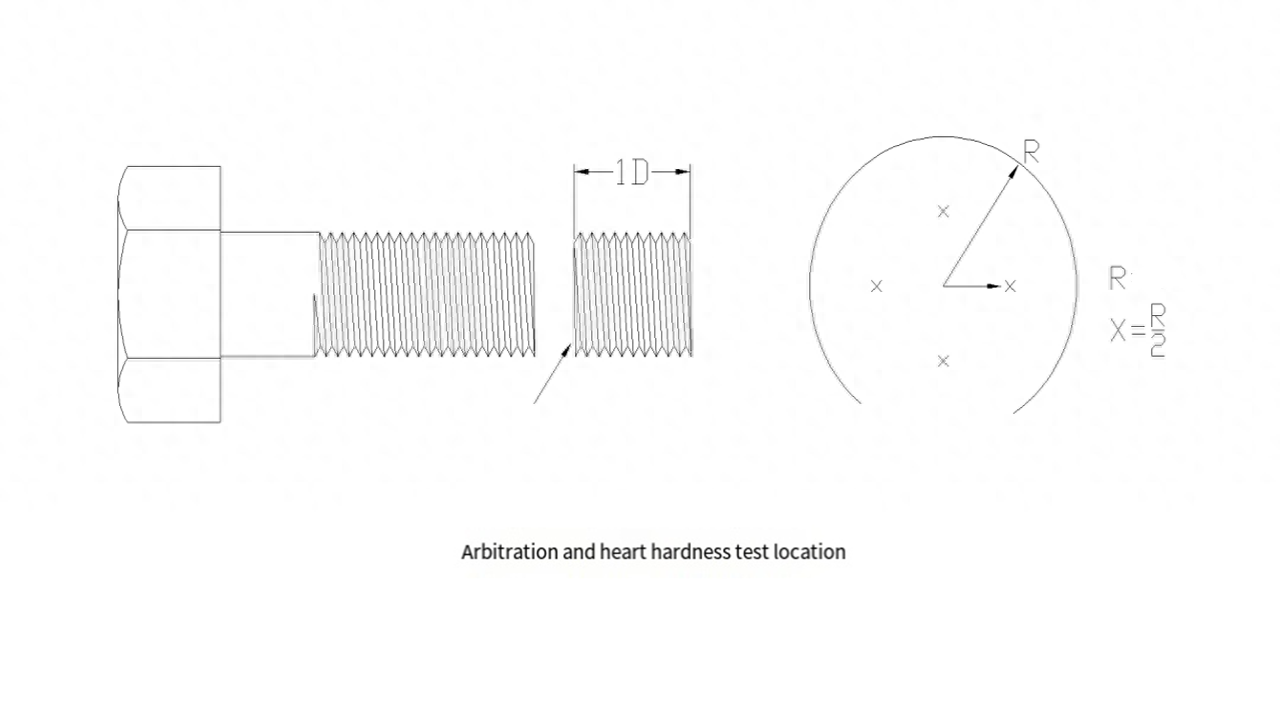

Ha ho fumanoa boima ba bolt, ha ho na phekolo ea mocheso ea li-bolts, ho hlokahala feela ho etsa boima ba holim'a metsi, ka har'a ange a tšoanelehang moleng.Haeba e le bolt ea phekolo ea mocheso, ho hlokahala hore u khaole boima bo holim'a bophara ba bophara qetellong.Boemo ba teko bo bontšoa setšoantšong.Teko ea boima e ka 1/2R holim'a metsi, 'me boima bo kopana le maemo.

Bolt thata e na le bokaholimo le motheo, bokaholimo bo bua ka tšebeliso ea Vickers kapa bokaholimo ba Rockwell thata ka mor'a ho tlosa mafome a holim'a metsi, joalo-joalo Theko e lokela ho ba ho tlosoa ha hlooho ea 1/2 bophara ba karolo e telele ka holimo le bohareng. 1/2 sebaka sa ho bapala ka thata, phapang pakeng tsa boima ba bobeli e ke ke ea feta 30HV, bokaholimo bo phahame ho feta 30HV bo bontšang hore carburizing ea holim'a metsi, ha e lumelloe, Haeba bokaholimo bo le ka tlaase ho 30HV, ho bolela hore bokaholimo bo fokotsehile. , 'me ha e lumelloe.

Nate e akaretsang ea sehlopha sa 8 e lokela ho phekoloa ka mocheso, empa ha ho na mocheso o alafshoang, linate tse tloaelehileng tsa sehlopha sa 8 hangata li entsoe ka tšepe ea 35, tlhahlobo ea boima e boetse e hlalositsoe, sebaka se akaretsang ha se hlokehe, moetsi oa phekolo ea mocheso. e leka boima ka mor'a phekolo ea mocheso, nate ea metric e atisa ho robeha ho tloha bohareng ho leka ho thatafala ha pelo ea eona, nate ea inch e atisa ho robeha sefahlehong se seng (ke hore, seha lithipa tse peli holim'a metsi), leka ho thatafala. ea bohareng ba karolo ea bokaholimo bo le bong, 'me linate tse nyane ka kakaretso li apesoa karolo ea 0.2 ~ Lekola boima ka mor'a 0.3mm.4.6 ~ 6.8 liboutu ha li hloke kalafo ea mocheso;E etselitsoe mofuta oa 2 oa linate tse phahameng.

Maemo a naha a GB3098.1 le a naha a GB3098.3 a bolela hore boima ba arbitration bo lekantsoe ho 1/2 radius ea karolo ea sefapano sa karolo.Haeba ho e-na le phehisano leha e le efe nakong ea ho amoheloa, Vickers hardness e tla sebelisoa e le tlhahlobo ea arbitration.Bonyane ho lokela ho nkoa ho baloa ha 3 bakeng sa sampuli ka 'ngoe.

Sebaka sa tlhahlobo ea Arbitration: Ha o tlaleha liphetho tsa liteko lipakeng tsa moreki le morekisi ka sepheo sa ho rarolla mathata, teko ea boima e tla lekanyetsoa sebakeng se bohareng (r/2) sa radius ea sebaka se khaotsoeng, bophara bo le bong ho tloha pheletsong ea sebaka. bolt kapa stud.Haeba boholo ba sehlahisoa bo lumella, nka lipalo tse 4 qetellong ea bolt kapa stud ena.Lihlahisoa tse nyane tsa bophara li ka boela tsa lekoa ho sebelisoa sebaka se bapileng sa bolt head terminal e tsamaellanang le sebaka se khaotsoeng se kaholimo.Bakeng sa tlhahlobo ea kamehla, ho thatafala ha liboutu, li-screws kapa li-studs li ka lekoa hloohong, mohatleng kapa shank ka mor'a hore ho tlosoe bokaholimo ka nepo.

Bakeng sa mekhahlelo eohle, haeba boleng ba teko bo feta moeli o ka holimo oa boima, mohlala o lokela ho tlosoa sebakeng sa bophara ba lebitso ho tloha qetellong ea mohlala, le bohareng ba mohlala le tsela ea khoele sebakeng se bohareng sa teko, boleng ba retest ha boa lokela ho feta moeli o ka holimo oa boima, haeba ho belaela, Vickers hardness (HV) e lokela ho amoheloa e le qeto.Teko ea ho thatafala ha holim'a metsi e ka fumanoa qetellong ea sehlahisoa kapa moeling oa hexagon, 'me sebaka sa teko se lokela ho theoha hanyane kapa se bentšitsoe ho netefatsa hore tlhahlobo e phetoa hape le boemo ba 'nete ba sebaka sa mohlala.HV0.3 e sebelisoa tekong ea arbitration ea teko ea boima ba bokaholimo.Boima ba holim'a metsi bo lekiloeng ka HV0.3 bo tla bapisoa le boleng ba tlhahlobo ea boima ba mantlha bo lekiloeng le HVo.3, 'me phapang e ke ke ea feta litekanyetso tsa boima ba 30 HV.Ho thatafala ha sefahleho ho feta ho thatafala ha mantlha 30 HV hardness values li bonts'a hore mohlala ona o entsoe carburized.Bakeng sa lihlahisoa tse nang le limaraka tsa 8.8 ho isa ho 12.9, phapang lipakeng tsa boima ba bokaholimo le boima ba mantlha bo ka sebelisoa ho fumana hore na sehlahisoa se na le carburizing holim'a metsi.Boima ba sehlahisoa ha bo amane ka ho toba le matla a theoretical tensile.Boikemisetso ba boleng bo phahameng ba boima ha bo thehiloe ho nahanoa ka moeli oa matla a holimo.

Tlhokomeliso: Ho lokela ho hlokomeloa hore phapang ea ho eketseha ha boleng ba boima bo bakoa ke phekolo ea mocheso oa carburizing kapa ho sebetsa ha serame.

Nako ea poso: Sep-23-2023